CONTACT US

Hotline:

South China:

400-882-9259

East China:

400-850-8066

Wechat:

CONTACT US

Hotline:

South China:

400-882-9259

East China:

400-850-8066

Wechat:

AT SERIES DRILLING CENTER

Built Rigid, Unshakable

The AT body uses high-strength HT300 cast iron (superior to standard HT250/200), reinforced with alloys. Its 3500kg mass ensures exceptional stability, damping vibration by 40%.

Ultra-Fast, Time-Saving

Its 20,000 rpm BBT30 spindle uses taper-face dual contact to surpass BT tooling limits, ensuring dynamic balance with ≤0.001mm radial runout for higher precision.

User-Focused Configuration

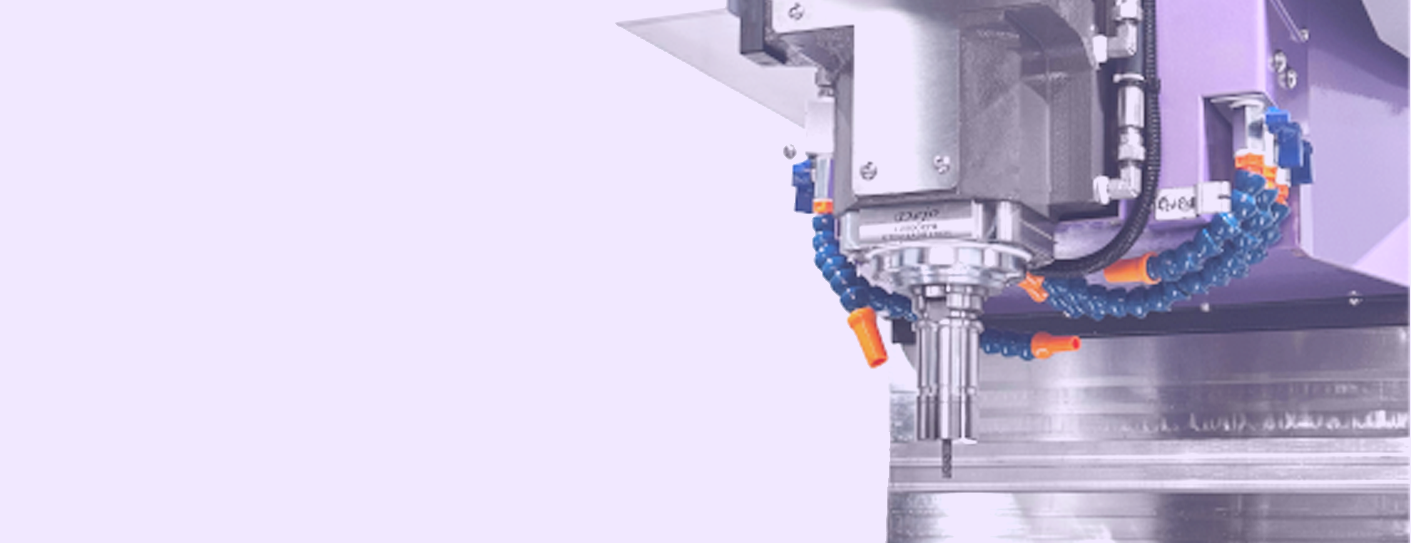

Enhanced Protection: Fully enclosed guards cut coolant splash and maintenance by 50%.

Intelligent Cooling: Spindle oil cooler ensures 12-hour continuous accuracy.

Flexible Options: Multi-CNC compatibility for custom adaptation.

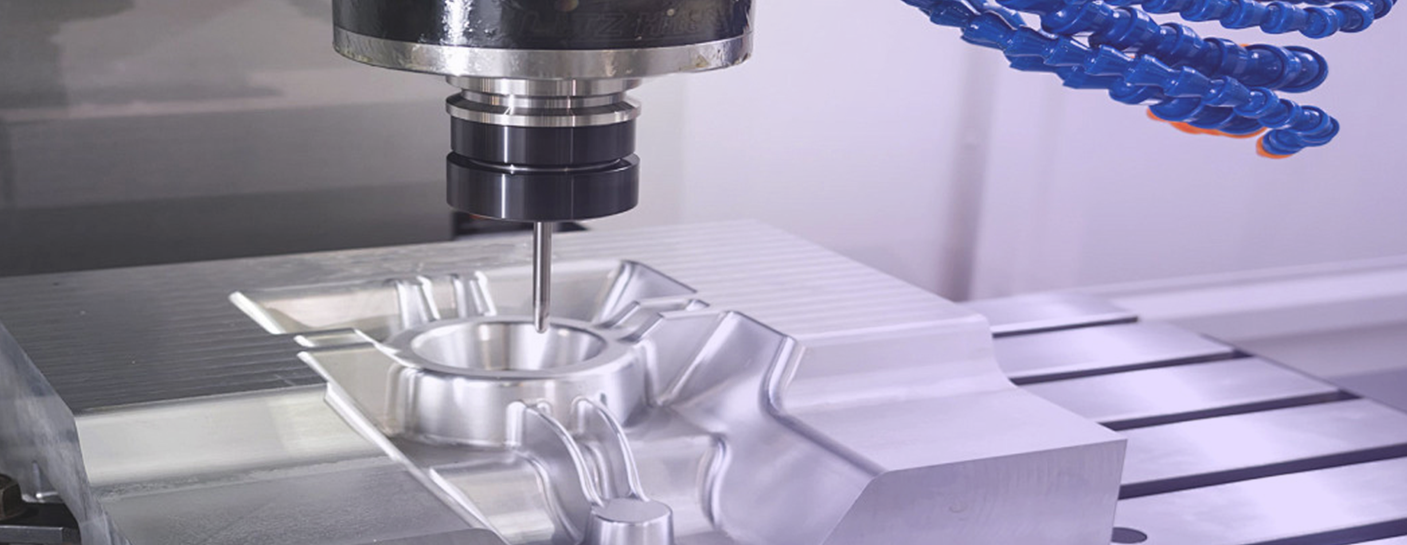

Precision Machining

ACCELERON breaks through drilling and tapping limits with revolutionary spindle technology: 20,000+ rpm BBT30 positioning combined with a 3500kg rigid structure ensures ±0.002mm precision, advancing the localization of core components for strategic industries.

Ultra-High-Speed Machining | Every Second Counts

Equipped with a 20,000 rpm ultra-high-speed BBT30 spindle system, it utilizes unique taper-face dual-contact positioning technology (breaking through the limitations of traditional BT spindle single-face constraint). The dual rigid contact interface ensures dynamic balance, controlling radial runout within 0.001mm and significantly improving machining accuracy.

Enhanced Protection

The fully enclosed guards combined with stainless steel inner lining effectively prevent coolant splash, offering corrosion and wear resistance while directly reducing maintenance costs by 50%.

Thermal Assurance

The spindle includes a standard oil cooler to prevent thermal deformation, ensuring precision over 12 hours of operation. With plug-and-play compatibility for Mitsubishi, Siemens, Fanuc, and other systems, it integrates seamlessly into existing workflows.

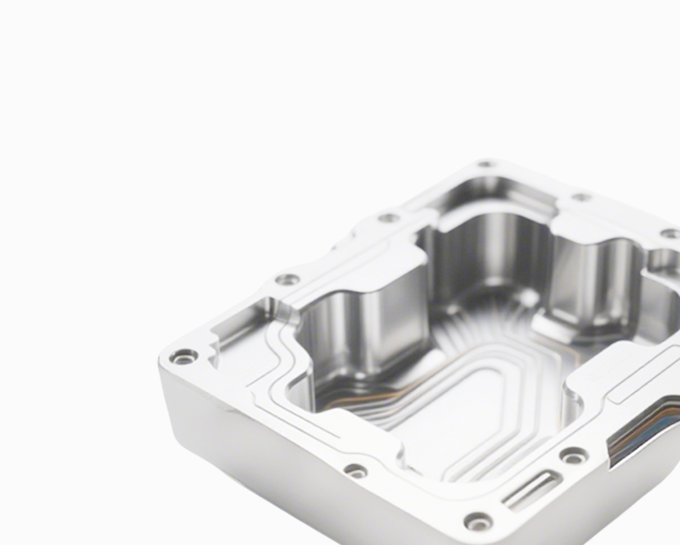

Precision Manufacturing | Crafted in China

ACCELERON breaks through drilling and tapping limitations with revolutionary spindle technology — combining 20,000 rpm ultra-high speed with a BBT30 taper positioning system. Supported by a robust 3500kg rigid structure, it achieves dynamic machining accuracy of ±0.001mm, advancing the localization of core components for strategic industries such as automotive and aerospace.