CONTACT US

Hotline:

South China:

400-882-9259

East China:

400-850-8066

Wechat:

CONTACT US

Hotline:

South China:

400-882-9259

East China:

400-850-8066

Wechat:

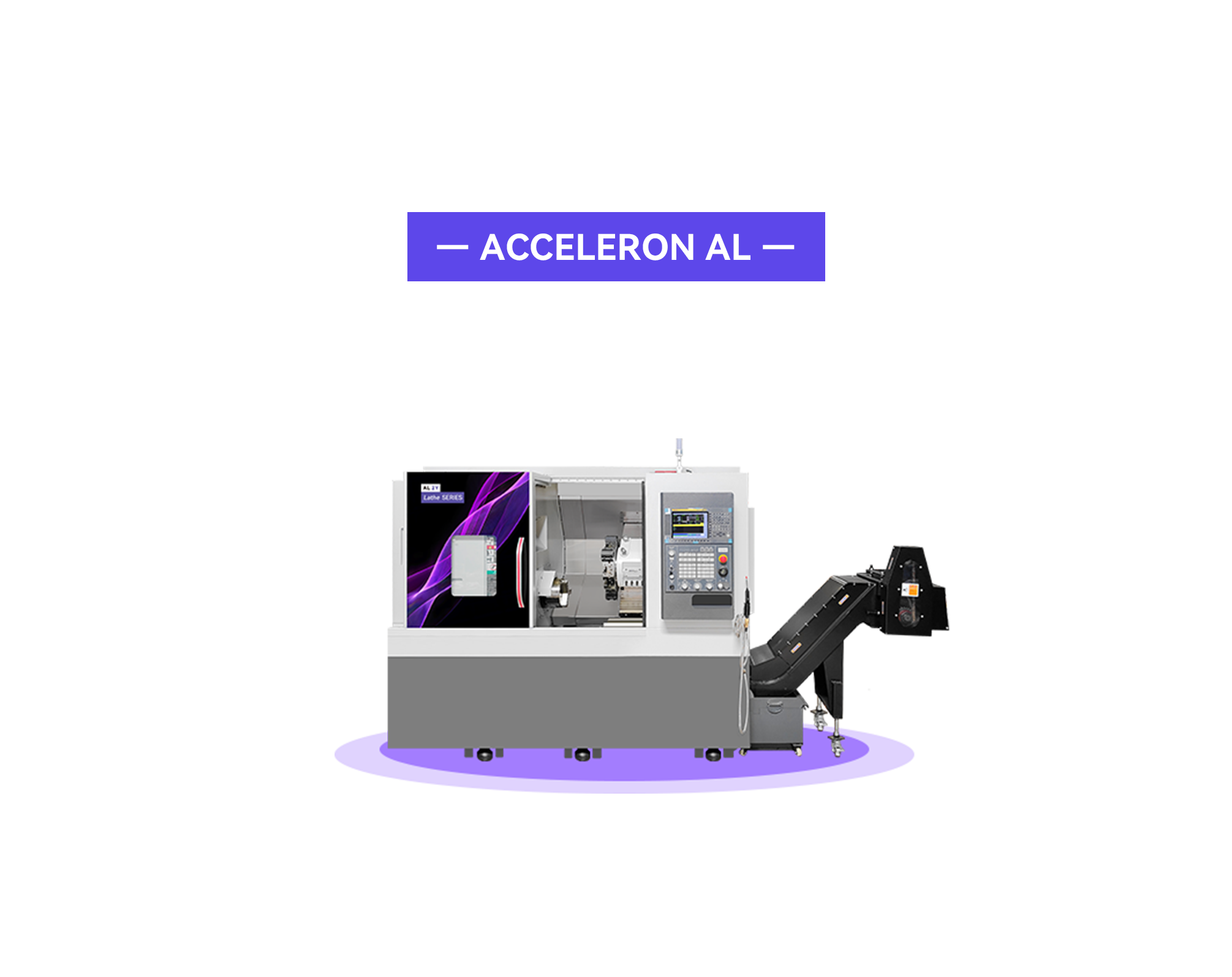

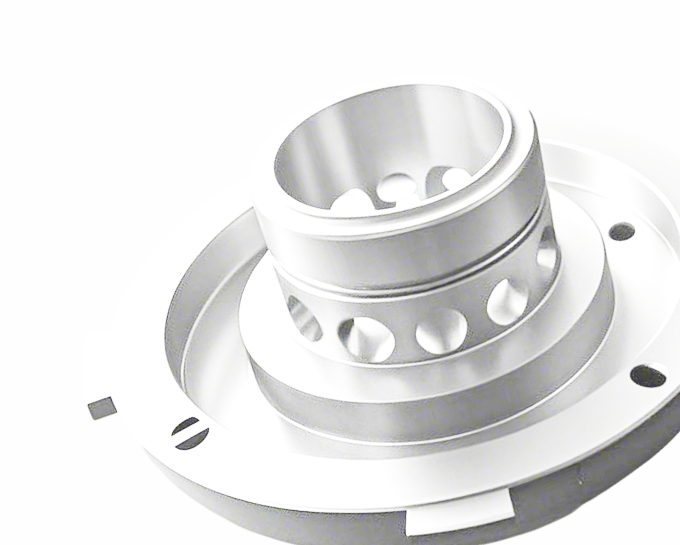

AL SERIES TURNING CENTER

High-Low Rail Monolithic Bed

Its modally-optimized center of gravity increases vibration resistance by 30%, enabling zero high-speed vibration and eliminating accuracy fluctuations in batch production.

Monolithic Structural Design

Integrated forging of the saddle, motor, and bearing housing eliminates assembly errors at the source, cutting vibration by 50% for industry-leading Ra 0.4–1.2μm surface finish.

One Machine, Multiple Capabilities

Its BMT55 turret with Y-axis enables efficient combined machining, integrating a 12-station servo unit for turning, milling, drilling, and tapping to boost complex part efficiency by 50% in one setup.

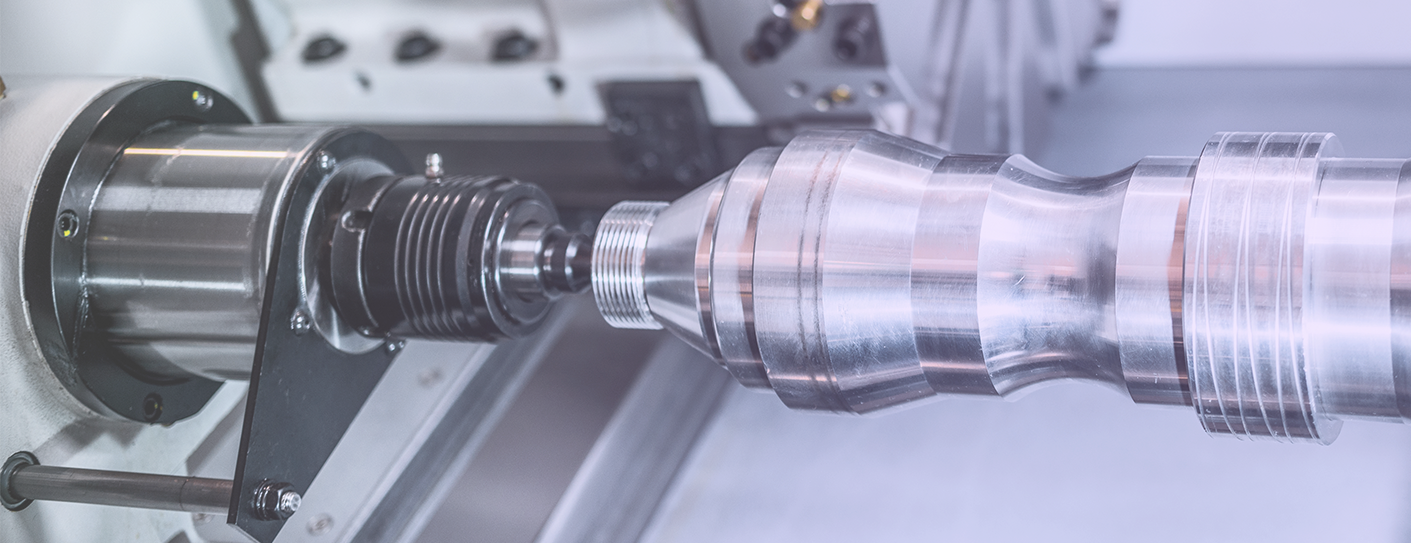

High-Performance Motorized Spindle

The AL series uses a 19kW direct-drive spindle (165Nm torque) to eliminate backlash, increase rigidity by 40%, and improve efficiency by 30% in hard materials at 4500rpm for A2-6 applications.

Direct-Drive Motorized Spindle

The AL series is equipped with a 19kW direct-drive motorized spindle, delivering 165Nm of high torque output. By completely eliminating traditional transmission mechanisms, it eradicates transmission backlash at the source. Radial and axial runout are significantly reduced, while dynamic rigidity is increased by 40%, enabling faster response, superior surface quality, and more stable machining accuracy.

Hard Material Machining

It machines tough materials like titanium and high-strength steels, achieving single-pass deep-hole drilling for aerospace. With 4500rpm and an A2-6 interface, it serves new energy and medical fields without reconfiguration, boosting efficiency by 30%.

Intelligent Control System

Equipped with the FANUC 0i-TF Plus intelligent control system, it achieves ultra-high positioning accuracy of ±0.003mm. Even beginners can easily handle complex programming tasks.

Material Savings & Stability

Paired with an 8-inch through-hole spindle, it supports continuous processing of long bar stock, increasing material utilization to 98% and significantly boosting batch production efficiency. An optional hydraulic servo tailstock enhances machining stability for long shaft components by 60%, effectively eliminating chatter and meeting high-precision shaft machining requirements.