CONTACT US

Hotline:

South China:

400-882-9259

East China:

400-850-8066

Wechat:

CONTACT US

Hotline:

South China:

400-882-9259

East China:

400-850-8066

Wechat:

AU SERIES FIVEERIES-AXIS VERTICAL MACHINING CENTER

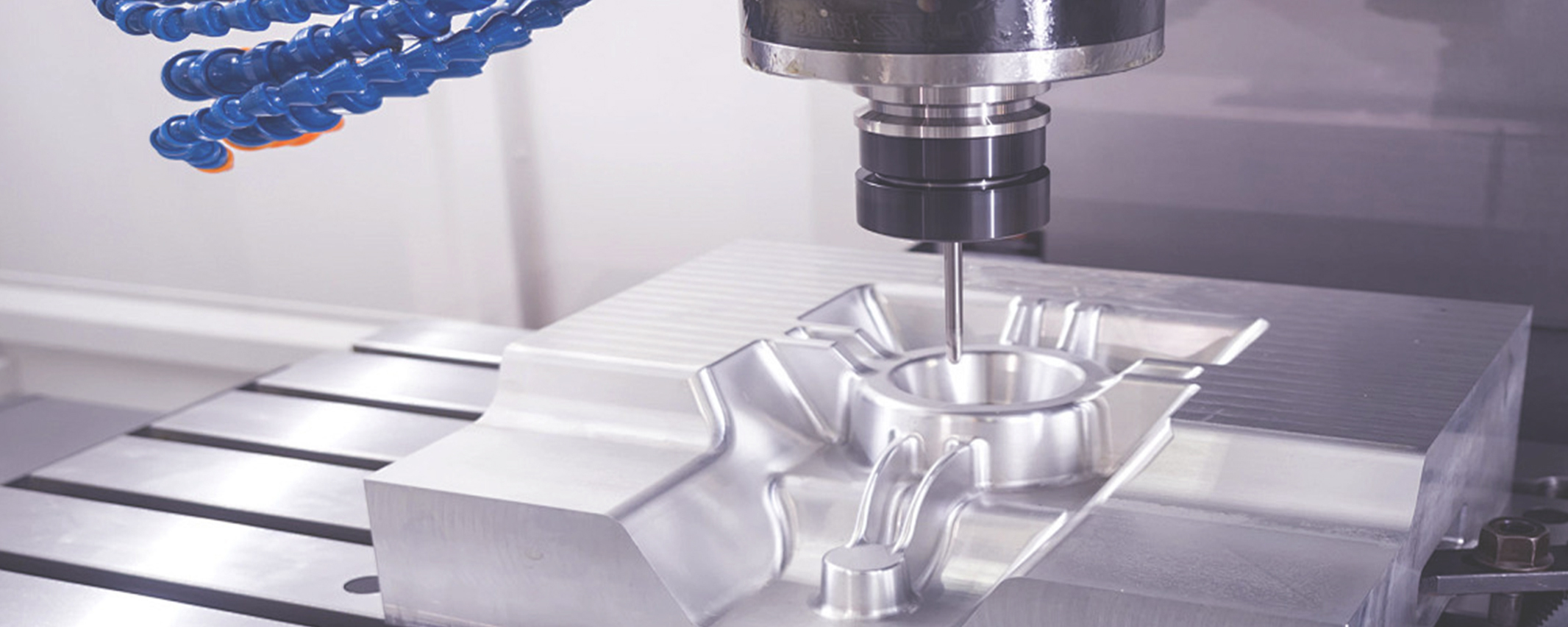

Single-Setup Machining

Full five-axis machining technology enables omnidirectional cutting through synchronized movement of all five axes. This allows complex surfaces and parts to be completed in a single setup, eliminating the need for repositioning and tool changes, saving time while ensuring precision.

Reduced Non-Cutting Time

By enabling direct machining of complex surfaces, five-axis machining eliminates the need for manual adjustments, measurements, and corrections typically required in traditional methods. This significantly reduces auxiliary operations and improves overall machining efficiency.

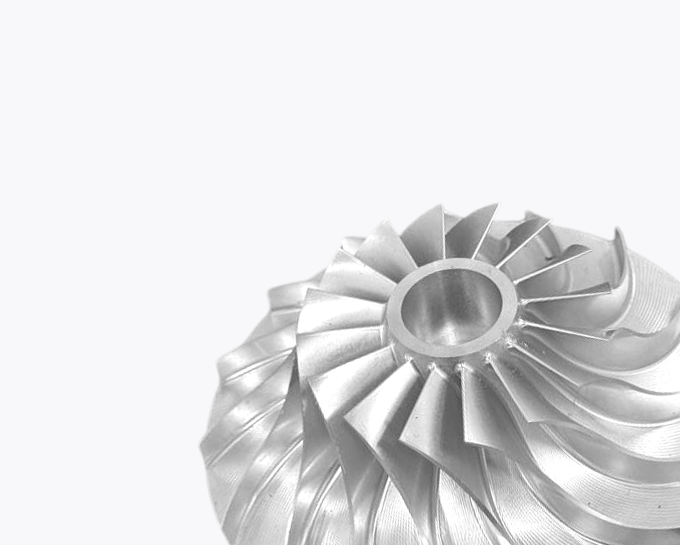

Improved Material Utilization

Through high-precision tool path planning and optimized cutting parameters, five-axis machining enables efficient material usage, significantly reduces waste generation, and lowers overall production costs—particularly suitable for high-value or difficult-to-machine materials.

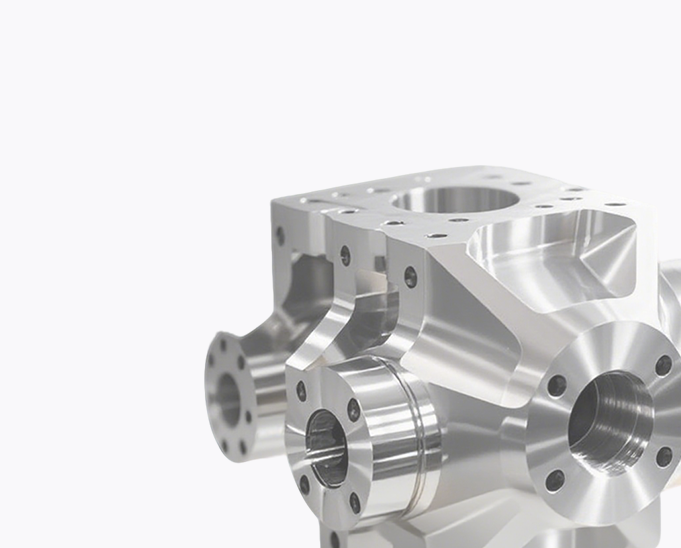

Self-Developed Hardware

Spindle: 18k–24k rpm for precision 3C & non-ferrous machining

Tool Magazine: 32-tool (→60) chain-type for continuous operation

Components: Rexroth/THK guideways & triple-aged HT300 bed

Five-Axis Precision

Our machine achieves 0.015mm fixed-position accuracy (vs. 0.03mm standard) and maintains <0.01mm fluctuation in 72-hour tests. It enables ±0.03mm 5-axis precision (vs. ±0.06mm standard), with original encoders and a triple-aged bed for single-setup complex surfaces. This performance surpasses domestic peers and matches over 90% of imported brands at a superior cost-effectiveness.

Full-Stroke Reliability

The A-axis features dual direct-drive motors, while the Y-axis incorporates full-stroke support. This design significantly enhances rigidity compared to traditional C-frame and cantilever structures.

Direct-Drive Table

Response speed is over 30% faster than gear-driven systems, with positioning accuracy of ±5 arc-seconds and repeatability of 4 arc-seconds. Combined with RTCP and full 5-axis closed-loop control, it delivers superior dynamic precision.

Self-Developed, Not Just Assembled

Motorized Spindle: 18k–24k rpm ultra-high speed, ideal for precision 3C and non-ferrous machining.

Chain-Type Tool Magazine: 32-tool capacity (expandable to 60), enabling continuous multi-process operation.

Top-Tier Components: Rexroth/THK guideways and triple-aged HT300 bed ensure long-term precision stability.