CONTACT US

Hotline:

South China:

400-882-9259

East China:

400-850-8066

Wechat:

CONTACT US

Hotline:

South China:

400-882-9259

East China:

400-850-8066

Wechat:

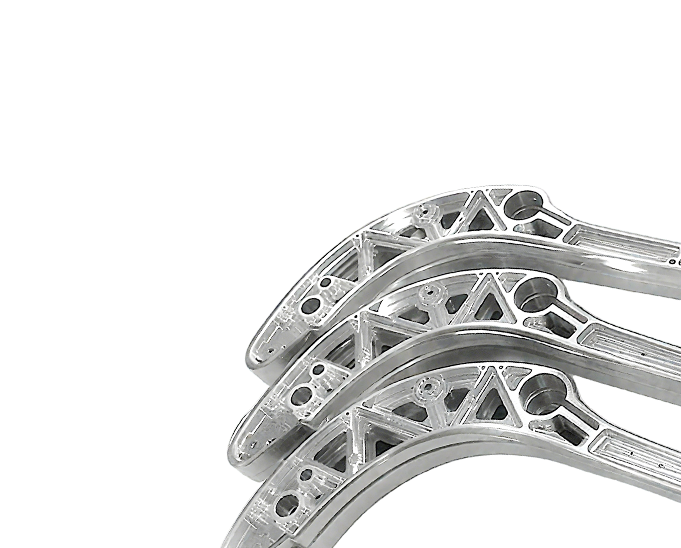

AM SERIES VERTICAL MACHINING CENTER

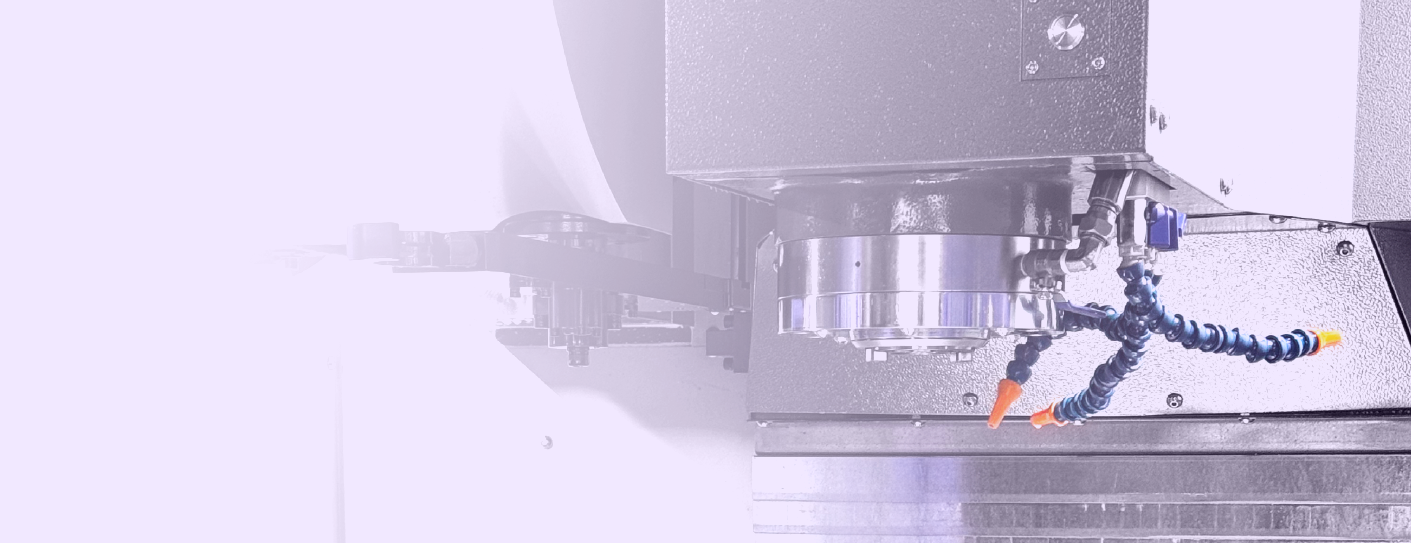

Robust Hardware

The standard BBT40 high-precision spindle, with a reinforced 160mm diameter, delivers 33kW and 15000 rpm to boost efficiency by over 20% with robust high-speed performance.

6-Block Roller Guideways

With heavy-duty European roller guideways and an extended 6-block Z-axis design, we boost load capacity over 30%, dampen vibration, and guarantee zero-deviation stability for precision molds.

Core Advantages

Its standard BBT40 high-precision spindle, with a reinforced 160mm outer diameter, delivers 33kW and reaches 15000 rpm to boost machining efficiency by over 20%, ensuring robust performance at high speeds.

High-Strength Bed Structure

The HT300 cast iron base, with an inverted W-rib design, increases vibration resistance by 40%. Its 6000kg mass ensures rock-solid stability in high-speed cutting for reliable, durable performance.

Versatility Across Scenarios and Materials

The AM series encompasses both Precision and High-Efficiency sub-series, catering to diverse industrial production needs. It supports the machining of 3C electronics housings and internal structures, new energy vehicle components and interior/exterior trims, high-precision aerospace parts, as well as medical devices, molds, and precision components for automation equipment. Compatible with a wide range of materials, it effortlessly handles complex surfaces, multi-hole machining, and other precision tasks.

Productivity ROI

The enclosed side-mounted magazine ensures fast tool changes with minimal downtime and footprint; the dual-coolant spindle enables efficient chip clearance and tool life extension, permitting deep-hole machining, higher feeds, better finish, and shorter cycles.

Efficient & User-Friendly

High-rigidity C-frame and Siemens 828D ensure stable, space-efficient operation and easy use. Durable roller guides and automatic systems reduce maintenance, replacement, and costs.

Full-Lifecycle Service Support

Localized Rapid Response:Our national network provides 24/7 hotline support and end-to-end service, from pre-sales solutions and installation to post-sales maintenance.

Smart Service System:Real-time CRM tracking and full repair history, integrated with IoT, enable remote monitoring and predictive maintenance, preventing unplanned downtime.